Press Release

Star Plastics Progresses on Long Term Waste-to-Landfill Reduction

For Immediate Release

Media Contact:

Scott W. Blanchard

Marketing Communications Leader

Phone: 330.322.8111

Email: sblanchard@starplastics.com

Millwood, W.Va. — November 11, 2025 — Star Plastics, LLC, a leading compounder of engineered thermoplastics, has released its first sustainability report, marking a milestone in the company’s efforts toward transparency, accountability and environmental progress.

Millwood, West Virginia – February 17, 2026 — Star Plastics, LLC, a leading custom compounder of engineering-grade thermoplastics, continues to make measurable progress toward reducing waste sent to landfills. Through disciplined operational improvements and a long-standing commitment to circular practices, Star has met—and in several cases exceeded—its year-over-year waste reduction goals.

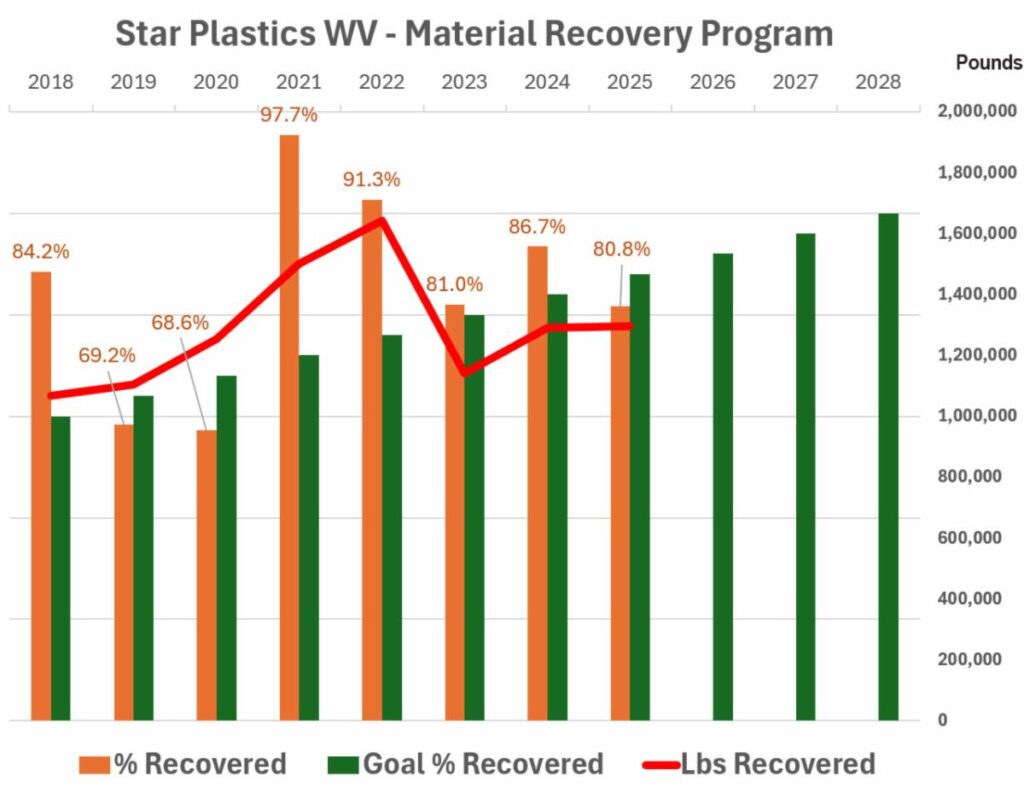

The company’s goal is to improve material recovery by 20% over a 10-year period, using 2018 as its baseline. Star’s waste-to-landfill strategy focuses on minimizing waste at the source and diverting material through reuse, recycling, and energy-recovery pathways. Since establishing baseline measurements, the company has steadily reduced the volume of material sent to landfill while increasing overall material recovery rates across its operations.

“Our sustainability goals aren’t aspirational statements—they’re operational commitments,” said Daniel T. McMullen, chief executive officer of Star Plastics. “Year after year, our teams are finding smarter, more efficient ways to keep materials in use and out of landfills. In many areas, we’re moving faster than planned, and that momentum matters—for our employees, our communities, and our customers.”

In five out of seven years, Star has recovered more material than its annual target, with 2021 and 2022 recording recovery rates exceeding the cumulative goal of 90%.

Delivering Results Year After Year

These improvements are driven by:

- Enhanced material segregation and recovery processes that reduce landfill dependency

- Continuous process optimization to limit scrap and rework

- Expanded internal reuse and recycling programs across facilities

- Employee-led initiatives focused on waste reduction at every stage of production

Together, these efforts have enabled Star not only to track progress toward long-term landfill reduction targets, but also to surpass interim benchmarks in multiple reporting years.

Built on a Circular Foundation

Founded as a post-industrial recycler, Star Plastics’ approach to waste reduction is embedded in its business model. Beyond internal operations, the company supports customers’ sustainability objectives through engineered materials designed with recycled content and circularity in mind.

“It’s an ongoing responsibility.” McMullen added. “We’re proud of the progress we’ve made so far, and we’re equally committed to pushing further—improving year after year and holding ourselves accountable through transparent reporting.”

Looking Ahead

Star Plastics will continue investing in process improvements, employee engagement, and material innovation to further reduce waste and improve recovery rates. The company views waste-to-landfill reduction as a critical part of delivering long-term value to customers while supporting environmental stewardship in the communities where it operates.

About Star Plastics

Star Plastics is a custom compounder of engineering-grade thermoplastics, specializing in recycled, flame-retardant, and UL-recognized materials. The company serves a diverse range of industries, including consumer electronics, electrical, lighting, appliances, transportation, furniture, industrial, and telecommunications. Headquartered in Millwood, West Virginia, Star Plastics operates manufacturing facilities in Millwood and Ravenswood, West Virginia; Evansville, Indiana; Calhoun, Georgia; and Shandong, China, delivering consistent, high-performance material solutions to customers around the world.

# # #