News

The Telescope — January/February 2026

Raising the Bar on Customer Service

At Star Plastics, reliability isn’t just something we talk about—it’s something we deliver, order after order.

In 2025, we achieved an on-time shipment rate of 99.61% across more than 2,500 customer orders. That level of performance significantly exceeds typical manufacturing benchmarks, where on-time delivery rates of around 95% are often considered strong.

What does this mean for our customers? Greater confidence in production schedules, fewer disruptions, and a partner you can depend on to deliver materials when you need them—without compromise.

This milestone reflects more than logistics alone. It’s the result of consistent product quality, disciplined order fulfillment, and a company-wide commitment to customer satisfaction. From operations and logistics to our labs, sales, and customer service teams, every group plays a role in ensuring your materials arrive exactly as promised.

As we move forward, our focus remains the same: keeping your operations running smoothly by delivering reliable materials—on time, every time.

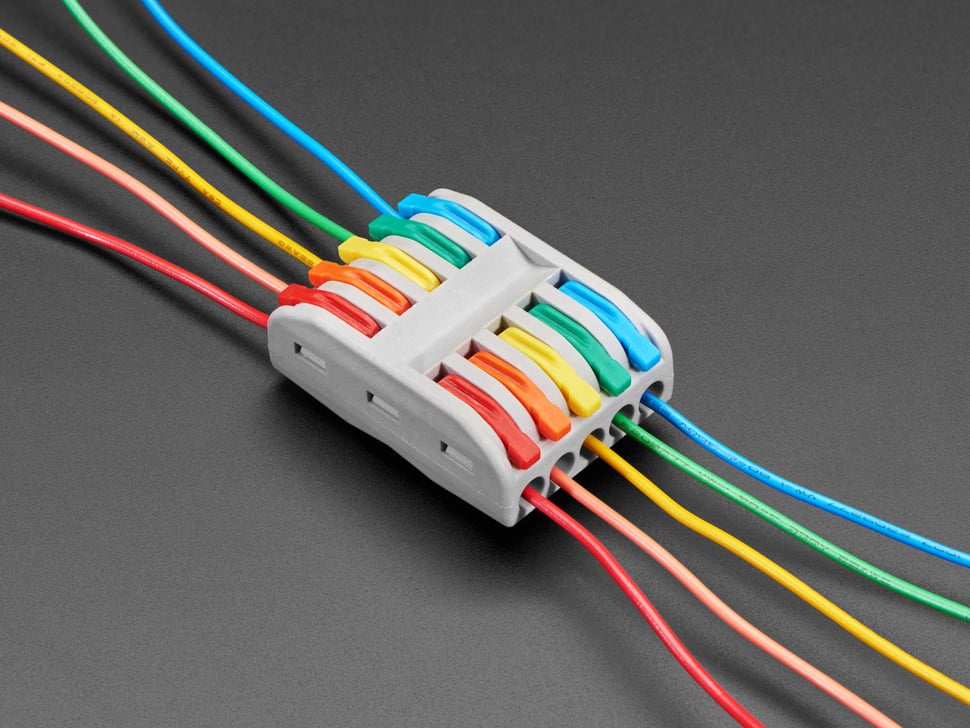

TriVET® Polyester Compounds: Proven Performance, Real-World Benefits

TriVET® is Star Plastics’ and Trivalence Technologies’ family of high-performance polyester compounds developed for demanding automotive, electrical, and industrial applications. Built on polybutylene terephthalate (PBT), TriVET materials provide excellent chemical resistance, dimensional stability, and electrical insulation, helping parts perform reliably in harsh environments.

TriVET® is Star Plastics’ and Trivalence Technologies’ family of high-performance polyester compounds developed for demanding automotive, electrical, and industrial applications. Built on polybutylene terephthalate (PBT), TriVET materials provide excellent chemical resistance, dimensional stability, and electrical insulation, helping parts perform reliably in harsh environments.

The TriVET portfolio includes impact-modified and glass-filled PBT grades, giving customers options to balance strength, stiffness, and toughness while maintaining consistent processing and part quality.

We also offer copolyester formulations that enhance durability and design flexibility for applications exposed to stress, vibration, or repeated use. Copolyester maintains higher impact and is BPA-free, making it suitable in many FDA and appliance applications such as appliance housings, electrical connectors, and oil and grease dispensing tubes.

For applications requiring enhanced impact and heat resistance, PBT/polycarbonate blends combine the best attributes of both materials. These blends retain strength at low temperatures, offer improved resistance to fuels and weathering, and reduce the moisture sensitivity commonly associated with crystalline PBT—delivering greater long-term performance and reliability.

With TriVET polyester compounds, customers gain materials engineered to support performance, consistency, and confidence—backed by the technical expertise of Star Plastics and Trivalence Technologies.

To learn more about TriVET products, fill out our contact form.

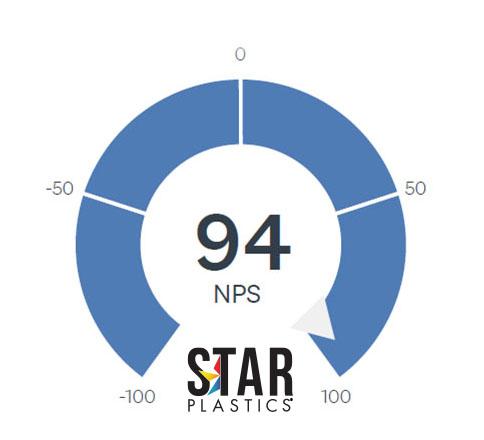

How Likely Is It That You Would Recommend Star To A Friend or Colleague?

This question defines what is known as the Net Promoter Score® (NPS), the likelihood of your customers to recommend your business to friends and colleagues.

This question defines what is known as the Net Promoter Score® (NPS), the likelihood of your customers to recommend your business to friends and colleagues.

Star Plastics earned a Net Promoter Score of 94 in our most recent customer survey.

An NPS this high is a direct reflection of the trust our customers place in us and the commitment our team brings every day. From responsive service to consistent product quality, this feedback reinforces that we’re delivering on what matters most.

A huge thank-you to you, our customers, for participating in the survey and for your continued partnership—and to our Star Plastics team for making results like this possible.

Days Without Lost Time

Private industry employers reported that 2.6 million nonfatal workplace injuries and illnesses . That number is a stark reminder of how critical workplace safety is, especially in high-risk industries like manufacturing.

Star has long embedded safety as a crucial part of its culture. This has extended to all Star locations, as you can see below. Listed are the current (as of this writing) days without a lost time incident.

| Calhoun, GA | 112 days* |

| Evansville, IN | 796 days* |

| Millwood, WV | 630 days* |

| Ravenswood, WV | 887 days |

This translates to an average of 606 days, or well over a year and a half. Star safety means customers can count on consistent quality, reliable supply, and peace of mind—knowing every material is produced with rigorous standards that protect their people, their products, and their reputation.

Plastics, LLC

Star is a leading custom compounder of engineering-grade thermoplastics with special emphasis on recycled, flame retardant and UL-approved materials.

Millwood, WV

Ravenswood, WV

Evansville, IN

Calhoun, GA

Shandong, China

326 Jack Burlingame Dr.

Millwood, WV 25262

304.273.0352

sales@starplastics.com

techsupport@starplastics.com